Aluminium Low Pressure Castings Filtration

Fiberglass Mesh Filter For Low Pressure Die Casting

Why the traditional metal wire mesh filters are not good for LPDC castings?

Galvanized steel or iron wire mesh filters are at present commonly used for low pressure castings filtration, especially for aluminum alloy wheels. The wire mesh filters are cost effective, with good strength and flexible on shapes and sizes. Now there is a new and better material to perfectly replace it due to the wire mesh filter has disadvantages.

Using the wire mesh filter, there will be largely Fe element added to the aluminum castings and this will lower the castings mechanical strength, especially for high quality standard, this means critical. For risers containing wire mesh filters after solidification, it can not remelted directly to furnace, even after the treatment. The direct cost is the risers had to be sold as scrap. It's great waste.

Fiberglass fabric mesh filters for aluminum filtration are specially designed and woven for the diffusion and filtration of molten aluminum. High twisted yarns are used to control strand diameters and resist flattening or distortion under pressure from contact with molten metal. The integrity of theweave pattern is maintained by the use of phenolic resin, and by the use of leno or Plain construction in high density. Regular coating and carbonized treatment are both available.

To use the fiberglass mesh filter to replace the traditional wire mesh filter and realize fiberglass aluminium filtration:

- Never change molten aluminum element or contaminate molten aluminum.

- No worry about the riser remelt anymore and easy to handle the aluminum scrap recycling.

- Fiberglass mesh can float on top of molten aluminum in furnace being remelt and recycled and it can be more easily scooped out.

- Reduces molten aluminum turbulence and improves distribution and flow.

- Remove oxides and inclusions to improve castings mechanical properties and surface finish.

- Excellent stiffness and toughness, good heat resistance.

aluminium filtration

Molded Fibeglass Filters For Low Pressure Die Castings

Sprue recycle now becomes easier

Convert from metal filter into fiberglass filter

We can design the new fiberglass filter for low pressure casting based on existing metal filter with only minor change to fit the sprue system.

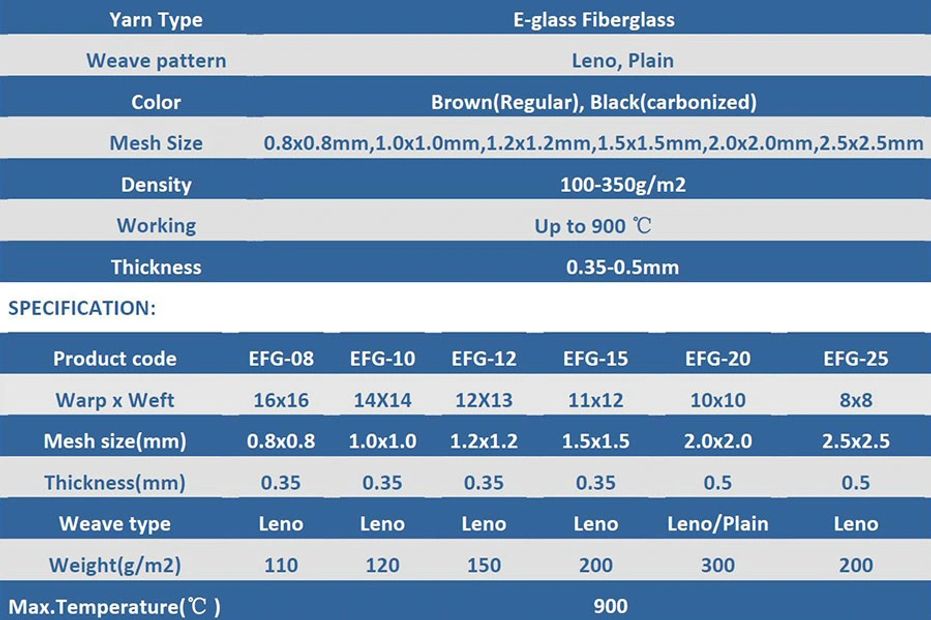

Filters Specification

Traditional metal wire mesh filter

New generation fiberglass mesh filter

You send us drawing, we do all the rest!

Mold layout drawings needed

Why we need the drawings

Metal filter for low pressure casting is differ from fiberglass aluminium filtration

Why we need the CAD files

That will be easier for us to adjust the low pressure casting filters sizes and shapes.

Copyright 2025 © Baoding Ningxin Group Co.,Ltd. All Rights Reserved

- Home

- Sic Ceramic Foam Filter

- Fiberglass Mesh Filter

- Silica Fabric Mesh Filter

- Sic Ceramic Foam Filter

- Sic Ceramic Foam Filter

- Ceramic Foam Filter AL2O3

- Alumina AL2O3 foam filter

- Ceramic Foam Filter ZR

- Zir Ceramic Foam Filter

- Extruded Ceramic Filter

- Ceramic Foam Filters

- Ceramic Foam Filters

- Quality

- Contact

- Blog

- Sitemap

- ZrO2 ceramic foam filter

Email: James@bdningxin.com.cn