Refractory cloth filter Silica fabric filters for molten metal filtration

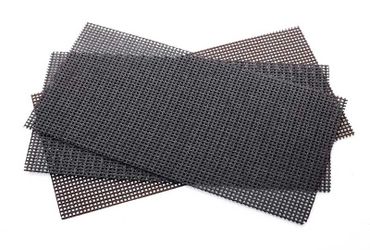

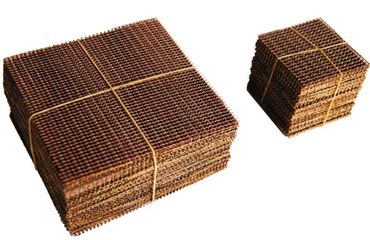

HIGH SILICA FIBERGLASS MESH FILTERS

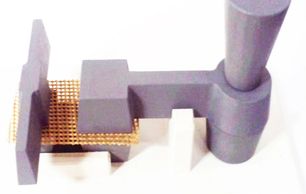

FIBRETE Silica Mesh Filter For Molten Metal Filtration

Silica mesh casting filter is weaved by high silica fiberglass yarn and coated with special refractory coating. It can effectively remove slag, refractory particles and non‐metallic inclusions from molten metals.

Made from specially treated silica yarns, the refractory cloth filter silica mesh are capable of withstanding pouring temperatures up to 1620℃. Silica mesh filters are ideal for in‐mold filtration of gray, malleable, white, ompacted graphite and ductile cast irons, as well as non‐ferrous aluminum and copper‐based metal alloys and many types of small scale steel casting filtration.

Features:

- Cost effective and easy to use, easy fit existing pattern equipment

- Eliminates inclusions created by ceramic chips

- Improves metal fluidity and distribution, reduce turbulence

- Removes micron sized inclusions and impuritie

- Minimize gating system to reduce cost

- No need for pre‐Heat, non‐chilling

Application:

In mold filtration including sand casting, gravity casting, shell mold casting etc.

Dimensions:

- Size available: 30x30mm/D30mm to 900x1000mm.

- Flat cut pieces shape: Round, square and rectangle. Other shapes available upon request.

Sand casting filter

Various sizes & SHAPES Available

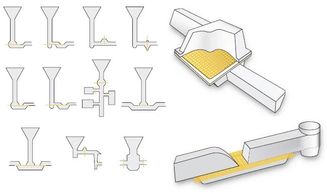

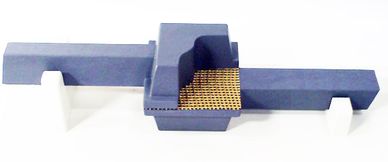

Filter position

Silica mesh filters user guide

The silica mesh casting filter can be located anywhere within the pouring system. The best results are obtained when the refractory cloth filter is placed as close as practical to the ingate.

SECTIONAL AREA:

Sectional Area of filter = Sectional Area without filter / (a x b)

a: Filter open area:50-60%

b: Filtration efficiency: 60-80%

So the sectional area with the filter is normally about 2-4 times that without a filter.

ATTENTION:

- Prevent high flow molten metal directly impact filters.

- Beware of oblique pull, abrasion and fracture, the filter size should be greater than size of section about 20-30mm.

- Handling care during load and unload,prevent extrusion.

Mesh sizes available

1.5x1.5mm, 2.0x2.0mm, 2.5x2.5mm, 3.5x4.0mm

Copyright 2025 © Baoding Ningxin Group Co.,Ltd. All Rights Reserved

- Home

- Sic Ceramic Foam Filter

- Fiberglass Mesh Filter

- Silica Fabric Mesh Filter

- Sic Ceramic Foam Filter

- Sic Ceramic Foam Filter

- Ceramic Foam Filter AL2O3

- Alumina AL2O3 foam filter

- Ceramic Foam Filter ZR

- Zir Ceramic Foam Filter

- Extruded Ceramic Filter

- Ceramic Foam Filters

- Ceramic Foam Filters

- Quality

- Contact

- Blog

- Sitemap

- ZrO2 ceramic foam filter

Email: James@bdningxin.com.cn